Constantly Facing Stockouts & Excess Stock? Don’t Panic! Learn Scientific Inventory Planning!

It is believed that the vast majority of Amazon sellers have encountered such problems: one is FBA stockouts, and the other is FBA inventory overstock, which cannot be sold. In the end, it seriously affects Listing rankings, order declines, profit losses, and even causes company cash flow crises.

Upon careful analysis, it is found that the reason for inventory overstock and stockout problems is that data was not properly calculated during inventory planning. Seeing orders come in, some sellers aggressively place orders frantically, while others are very conservative and unwilling to replenish stock, eventually going further and further down the road of clearance or stockouts...

So, how exactly should we calculate reasonable stock levels to ensure healthy inventory turnover? SellerSpace will teach you five tricks to easily solve inventory planning problems!

01. Estimate Daily Sales

As an excellent operations manager, the first thing is to clearly understand the recent sales performance of products, which is a prerequisite for scientific inventory planning.

The measurement of daily sales needs to be balanced based on sales fluctuations. Because factors such as peak seasons, holidays, promotions, and discount力度 will cause large fluctuations in sales data at different time periods. If the sales volume of a specific day is used for inventory planning, it will lead to large differences in the suggested stock level, and the inventory planning will be inaccurate.

Therefore, in order to improve the accuracy of inventory planning, the weighted average of sales in the last 3/7/14/30 days can be used as the daily sales of the entire product to participate in the subsequent logical calculation of inventory planning.

+

+

(Source: SellerSpace -> Inventory Analysis feature)

02. Estimate Lead Time

Lead time refers to the total time required from placing an order with a supplier to receiving the products in the Amazon FBA warehouse. Lead time affects the seller's cash flow. The shorter the lead time, the shorter the inventory planning time for the product, and the less capital is occupied.

Therefore, we must learn to accurately estimate the product lead time. The commonly used lead time calculation formula is: Lead Time = Purchase Planning Days + Procurement Days + First-Leg Shipping Days

+

+

(Source: SellerSpace -> Inventory Analysis feature)

As shown in the figure above, the lead time of this product is 40 days. At this time, you can compare and analyze the sellable days of the product with the lead time:

- If the sellable days are less than 40 days, it means that inventory planning is needed;

- If the sellable days are slightly greater than 40 days, it means that the inventory is in normal turnover;

- If the sellable days are much greater than 40 days, it means that there is redundant inventory, which needs to be cleared in time to avoid high storage fees.

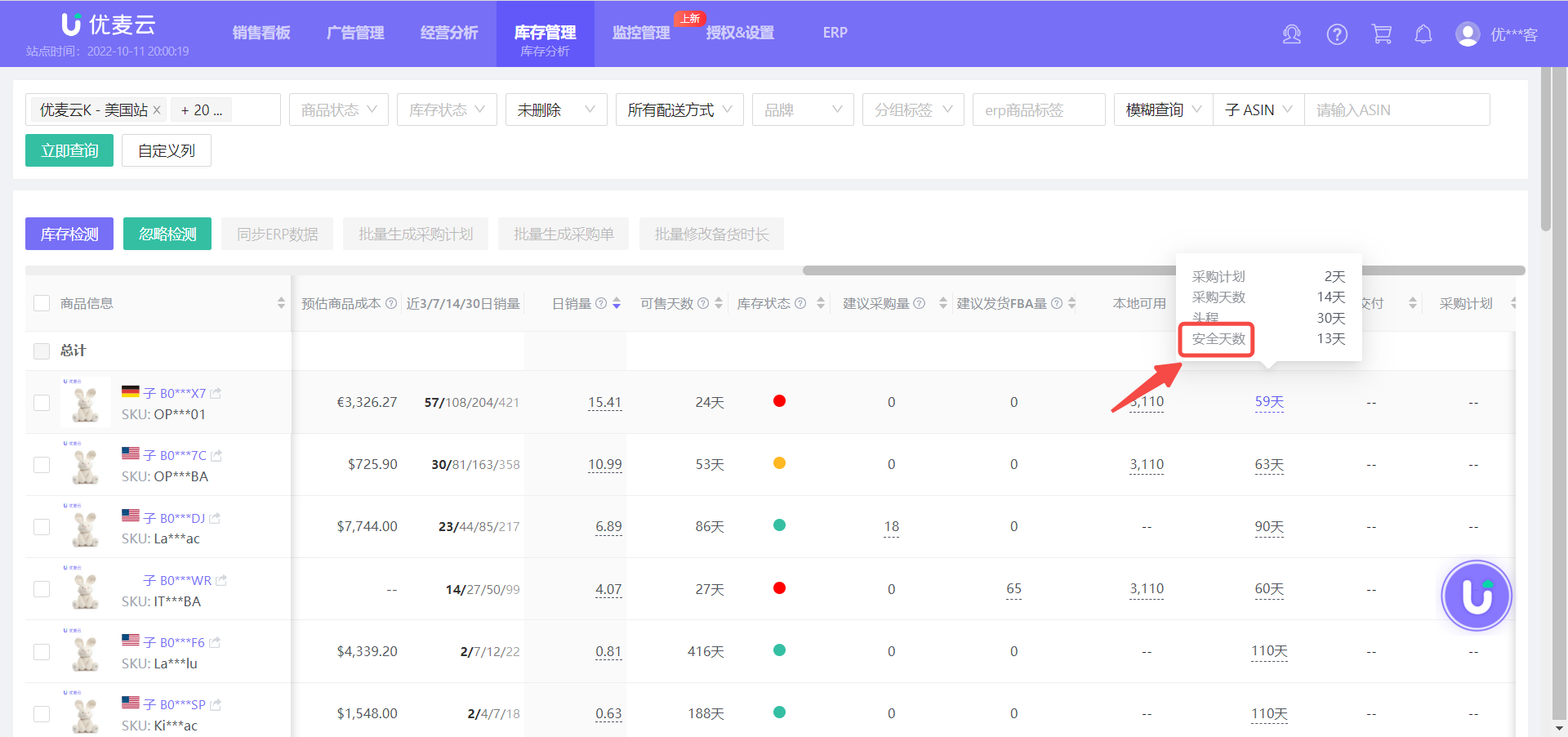

03. Determine Safety Stock Days

It is an ideal situation that the sellable days of a product are exactly equal to the lead time, but reality is often more complicated than ideal. Therefore, we also need to consider other uncertain factors that may cause the lead time to be extended. For example:

- The impact of the COVID-19 pandemic, factories cannot resume work, and the delivery cycle is extended;

- Amazon warehouse explosion, queuing for warehousing, and the required last-mile time;

- Customs spot checks, waiting days for customs clearance of goods;

- ……

The buffer time that needs to be prepared to prevent stockouts due to procurement, logistics or other uncertain factors is the safety stock days. Generally speaking, Safety Stock Days ≥ Purchase Planning Days + Procurement Days + First-Leg Shipping Days.

Operations personnel need to set appropriate safety stock days according to the actual shipping situation. It should be noted here that the longer the safety stock days, the more secure it is not. Too long safety stock days may lead to excessive inventory planning.

Excessive inventory planning will not only lead to high capital pressure, but also reduce Amazon's IPI inventory index, affecting the normal operation of the store.

+

+

(Source: SellerSpace -> Inventory Analysis feature)

04. Statistics of Existing Inventory

Existing Inventory = Sellable + Inbound + Reserved + Under Investigation + Unsellable + Local + Inventory in Procurement.

The SellerSpace system automatically crawls and summarizes the existing inventory, and combines the daily sales and inventory planning lead time set by the seller to automatically calculate the suggested purchase quantity and suggested FBA shipment quantity, helping sellers avoid stockout risks and reduce inventory overstock at the same time.

+

+

(Source: SellerSpace -> Inventory Analysis feature)

05. SellerSpace - Intelligent Replenishment Suggestions

Regarding replenishment, the more traditional method is: manual calculation or experience judgment. However, this not only takes a lot of time, but the calculated results are not necessarily accurate, especially for best-selling products, with high sales and large replenishment quantities, the results calculated manually vary greatly.

SellerSpace helps sellers build an efficient and intelligent replenishment model based on the following two aspects:

- Pay attention to the inventory of best-selling products, out-of-stock products, and slow-selling products, and provide replenishment suggestions based on the inventory planning lead time and daily sales of each product;

- Combined with the current Amazon inventory and local inventory, the optimal purchase and shipment quantity is obtained to avoid stockouts of best-selling products and affect sales, reduce warehouse inventory, and reduce the risk of slow-selling.

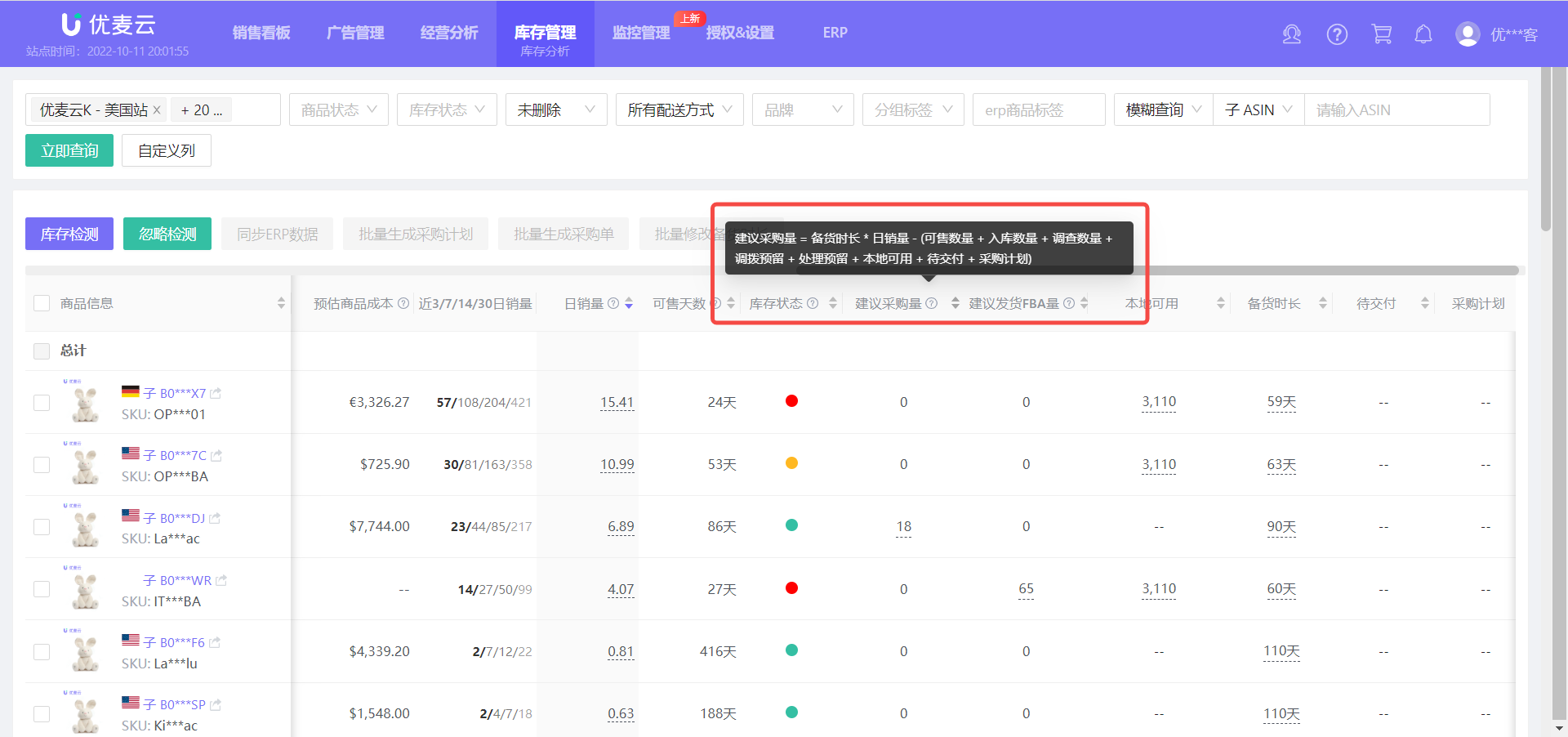

1. Suggested Purchase Quantity

Suggested Purchase Quantity = Inventory Planning Lead Time * Daily Sales - (Sellable Quantity + Inbound Quantity + Investigation Quantity + Transfer Reservation + Processing Reservation + Local Available + Pending Delivery + Purchase Plan)

+

+

(Source: SellerSpace -> Inventory Analysis feature)

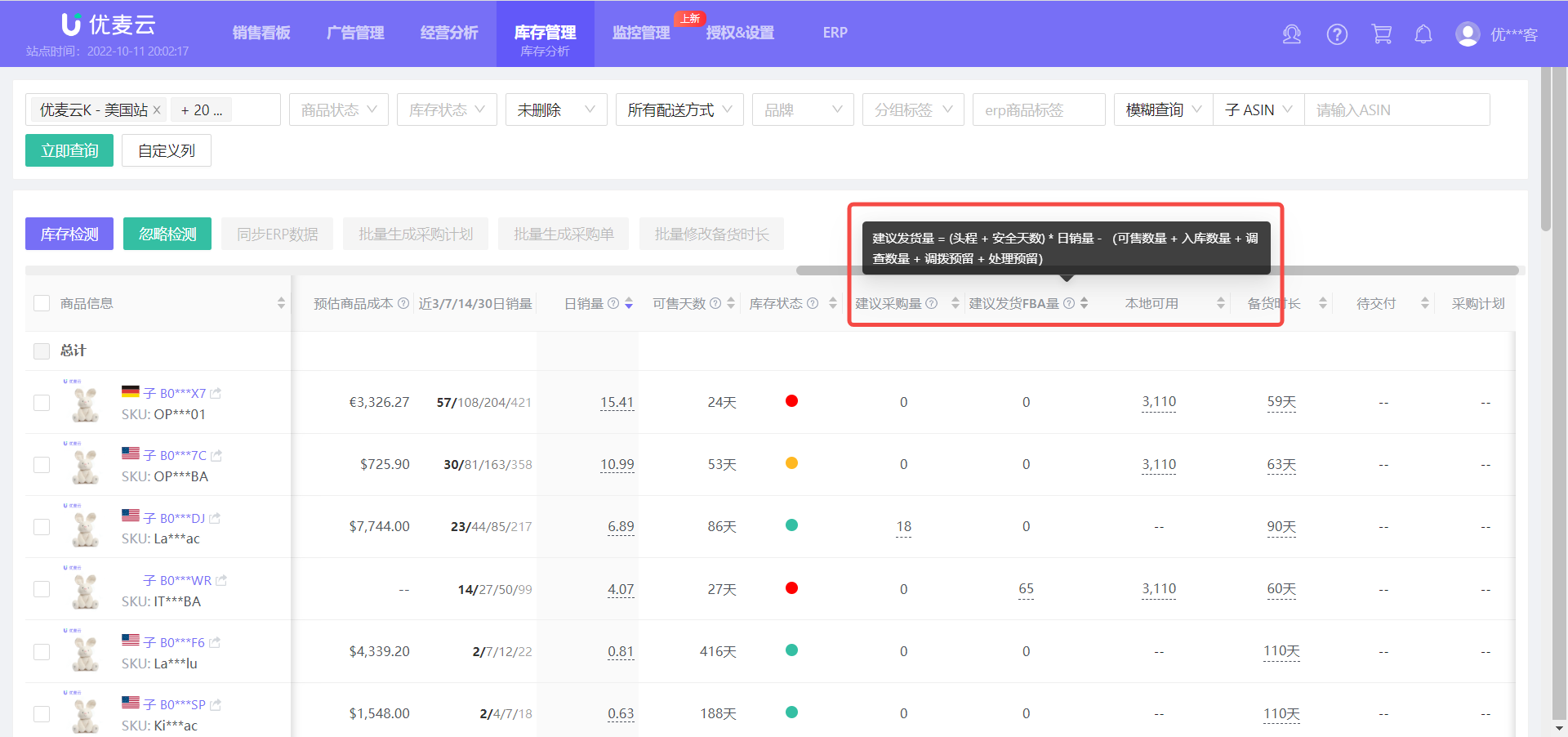

2. Suggested FBA Shipment Quantity

Suggested FBA Shipment Quantity = (First-Leg Shipping Days + Safety Stock Days) * Daily Sales - (Sellable Quantity + Inbound Quantity + Investigation Quantity + Transfer Reservation + Processing Reservation)

+

+

(Source: SellerSpace -> Inventory Analysis feature)

The above is the conventional logic of scientific inventory planning for Amazon. Mastering product sales details, combined with the actual warehousing and logistics inventory planning and delivery process and time, and using reasonable tools at the same time, can make inventory more focused and more efficiently handle inventory planning problems, and cope with possible inventory crises in the process of creating best-selling products!

SellerSpace is a concise tool to manage multiple Amazon accounts, focuses on solving various problems encountered by sellers during operating Amazon business.

Mail:support@sellerspace.com

©2018-2025 SellerSpace.COM All Rights Reserved

Online

Service